Appoints Industry Veteran Todd Mitchell as Regional Director - West

December 14, 2021 – USTC Corp, the leading one-stop shop for all materials, distribution, and supply chain management solutions for telecommunications, HFC, FTTH, FTTx, wireless, data center technologies, and electric cooperatives, announced the expansion of their sales group in the Western region of the U.S., and appointed Todd Mitchell as Regional Director, working for Comstar Supply powered by USTC. In this role, Mr. Mitchell will leverage his broad industry and sales experience as well as the Group’s extensive broadband and network infrastructure expertise to lead the company’s sales expansion and extend their offering of state-of-the-art products and solutions with their signature customer-centric approach to independent telecommunications companies and electric cooperatives in the region.

Mr. Mitchell brings nearly a decade of experience in the electric and telecommunications industry in sales leadership positions at Codale Electric and Irby Utilities, most recently serving as National Director of Sales for Irby, responsible for their national footprint and growth of telecom sales and operations. In his new position, Mitchell will drive the group’s growth, and continue the development of business and sales talent throughout the region.

Mr. Mitchell brings nearly a decade of experience in the electric and telecommunications industry in sales leadership positions at Codale Electric and Irby Utilities, most recently serving as National Director of Sales for Irby, responsible for their national footprint and growth of telecom sales and operations. In his new position, Mitchell will drive the group’s growth, and continue the development of business and sales talent throughout the region.

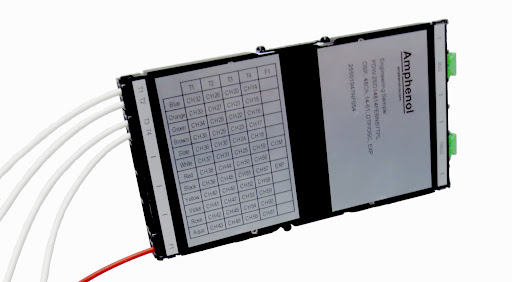

Earlier this year, USTC Corp acquired Comstar Supply and Walker, and together the three complementary organizations have created a unique offering with seven distribution locations across the U.S. The group has more than 70 years of combined expertise, experience, and performance supporting telecommunications, broadband, and rural electric cooperatives. With an extensive and comprehensive portfolio of 17,000+ products from over 750 industry-leading suppliers, and world-class logistics solutions, the group supports thousands of carriers’ full range of products and solutions for seamless delivery of high-speed Internet, Video, Data, and Voice Services to Residential, Business, and Mobile Users. The Western Region sales branch will help provide the reliability and flexibility needed for network upgrade, maintenance and deployment for electric cooperative, telecommunications, and broadband business in the region with best-in-class solutions and first-rate customer service.

“Todd brings vast sales management experience and deep industry relationships in the region. His addition strengthens our ability to scale the organization and help us further our world-class customer service for our valued customers.” said Punchard.

Added Mitchell, “I’m incredibly grateful to be joining the team, and I’m eager to continue the group’s sales momentum. We have an unprecedented opportunity to bring broadband solutions to a new set of customers and I look forward to expanding our sales operations in the western region.”

The appointment of Mitchell continues USTC’s investment in creating more American jobs across the 3 organizations collectively. The company expects to hire additional sales support to serve the western region under Mitchell’s leadership and will quickly deploy those resources to serve customers.

About USTC Corp

Together, USTC Corp, Comstar Supply, and Walker have created a leading one-stop shop for all materials, technical expertise, supply chain management solutions, and the value-added distribution of passive and active equipment and tooling from over 750 global suppliers for telecommunications, HFC, FTTH, FTTx, wireless, and data center technologies. Founded in 2017 by CEO and Chairman of the Board, Cédric Varasteh, the company is headquartered in Edison, NJ, with expanded operations in Dallas, Texas; Winston Salem and Raleigh, North Carolina; Philadelphia, Pennsylvania; and Reno, Nevada. With flexible delivery models, a plug-and-play approach, and modular set of value-added services, USTC Corp believes that customers deserve customization. Their experienced team of over 400 employees across 7 facilities in the U.S. are working hard every day dedicated to customer satisfaction and reliability. To learn more, visit www.ustc-corp.com and follow USTC Corp on LinkedIn at www.linkedin.com/company/USTCcorp.