What a wild ride it’s been for all of us at

Comstar in 2021, and we’ve still got 3 months left in the year!

When we published our last newsletter back in

March, Comstar had just begun to think about bringing people back into the

office and out on the road as we looked forward to some sense of normalcy in

our everyday work lives. Fast forward six months later, I’m happy to report

we’re back to near full capacity in the office and finally catching up

in-person with customers and prospects alike.

Yet it seems like the tides continue to shift as

the country struggles to adapt to the virus. We’re seeing it in the rising

number of COVID cases, and we’re experiencing it in disruptions to the global

supply chain. As you’ll read in this edition of our newsletter, China recently

announced a shutdown

one of the world’s busiest container ports

due to a virus outbreak. If that wasn’t enough, “container prices

have soared, with the benchmark cost of shipping a container up more than 220%

over the past year.” Because of these issues, it makes more sense than ever for

our customers to have a plan

B of

pre-approved material in case of any more significant interruptions to

production or the supply chain.

However, the most exciting news for us was in

August, when we announced that Comstar Supply was sold to USTC Corp., which is

backed by Washington, D.C.-headquartered global investment firm Carlyle Group.

USTC, a leading value-added distributor of telecommunications materials, supply

chain solutions, and technical expertise, also recently purchased Walker &

Associates, and combined, we will be a growing force in the broadband

distribution space.

USTC matches the employee focus and principles

we support, which is to value the people who do the work as well as the work

they do. This shared creed, on top of creating new and exciting opportunities

for our employees, were crucial initiatives for this partnership. In addition,

we’re also keeping our brand and leadership team, and will still have the

autonomy to shape our growth decisions.

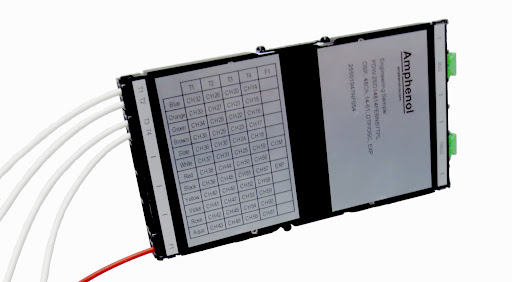

So, what does this mean for our customers?

Greater scale and increased buying power with the combined companies. Access to

seven distribution centers domestically. New products and capabilities

including material, product design, and value-added distribution of passive and

active equipment and tooling. And a combined company that creates the largest

Prysmian fiber distribution partner in the world.

For me, this opportunity is all about hyper

growth. It was critical for us to gain a partner who was willing to invest in

the business and support our growing customer base. As you all know, Comstar is

backed by a special group of employees, but there was a ceiling for us given

our company structure and limited capital resources. The partnership with USTC

catapults the combined companies into a leadership role as a domestic

distribution powerhouse that will continue to outperform competitors by placing

a focus on customer service and support.

A maxim of mine that we’ve preached to our team

is that change is inevitable. The foundation for us to react to market

conditions, withstand weather-related storms, literally, and adjust to the

changing needs of our customers, have steeled us in our ability to embrace

opportunities. We were built to succeed in this industry, and we will continue

to thrive in it. This opportunity with USTC allows us to scale the business

while maintaining the company we have all come to know and love.

Nearly 30 years ago, my father founded this company to support the OSP broadband industry through honestly, integrity, and hard work. I believe he would be extremely proud that we were able to grow it to the point of adding such strong international and domestic partners in USTC Corp., and the Carlyle Group.

As always, I appreciate your faith and trust in

us, and look forward to fulfilling your OSP material needs.

Thank you for your unwavering support.

Warmest regards,

Chad R. Punchard

President

Comstar Supply, Inc.